Authored By:

S.M. Choquette1 and I.E. Anderson

Iowa State University

Ames, IA, USA

Summary

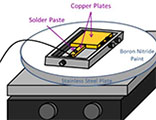

Continued research on a prototype paste, consisting of a composite mixture of SN100C (Sn-0.7Cu-.05Ni+0.01Ge) commercial solder powder and Ames Lab's gas atomized Cu-10Ni, wt.%, powder is being completed to improve the reliability and survivability of PCB and SMT solder joints operating under extreme temperatures (< 500 Celsius). The designed paste is predicted to be nearly 4,000 times less expensive than the currently available HTLF (hightemperature lead-free) solder Au-20Sn, wt.%, and able to withstand higher temperatures while still maintaining a standard commercial processing temperature of 250 Celsius.

The paste performs using liquid-phase diffusion bonding (LPDB) of the high-melting Cu-10Ni powders into the low melting SN100C to form the room-temperature stable intermetallic compound (IMC) (Cu,Ni)6Sn5. The nickel addition to this high-temperature phase increases joint ductility by suppressing the transformation of the IMC into the brittle low-temperature phase that would otherwise occur. Current research includes exploring the effect that powder size has on void formation in the joint. Existing results suggest that this composite solder could be a superior "drop-in" replacement for the Pb-based high-temperature solders that will soon be eliminated by RoHS restrictions.

Conclusions

From this experiment, two blends of Cu-10Ni composite pastes with varying Sn-alloy powder sizes were tested for their porosity. On average, the paste containing the smaller SN100C powder size (Type 6, 5-15 μm) resulted in solder joints with less porosity. The smaller powder size also helped create a more complete bond with the joint's substrate. The compositions of the phases were all as desired, including the previously unmodified (with Ni) IMC phase lining the Cu substrate.

Initially Published in the SMTA Proceedings

|