Authored By:

Bjorn Dahle, President, KIC

16120 W Bernardo Drive

San Diego, CA 92127 USA

http://kicthermal.com/

Transcript

How can you measure a BGA component thermal profile without destroying the BGA component in the process?

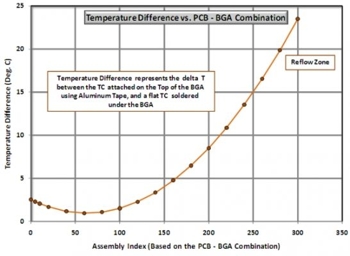

The Rochester Institute of Technology recently conducted a comprehensive study to measure whether there was any correlation between the temperature underneath a BGA component using a flat bead thermocouple, and a thermocouple attached on top of the component using aluminum tape.

A correlation was indeed found, which means that electronic assemblers can attach a thermocouple on top of the BGA component and use an offset to determine the temperature underneath. When attaching the thermocouple with aluminum tape, which can be peeled off afterwards, you can profile the BGA in a non destructive way.

The offset is dependent on each particular application. A free Excel calculator is available from KIC which enables a user to identify the offset specific to the application.

For more information see:

Temperature Difference Calulator By KIC

|